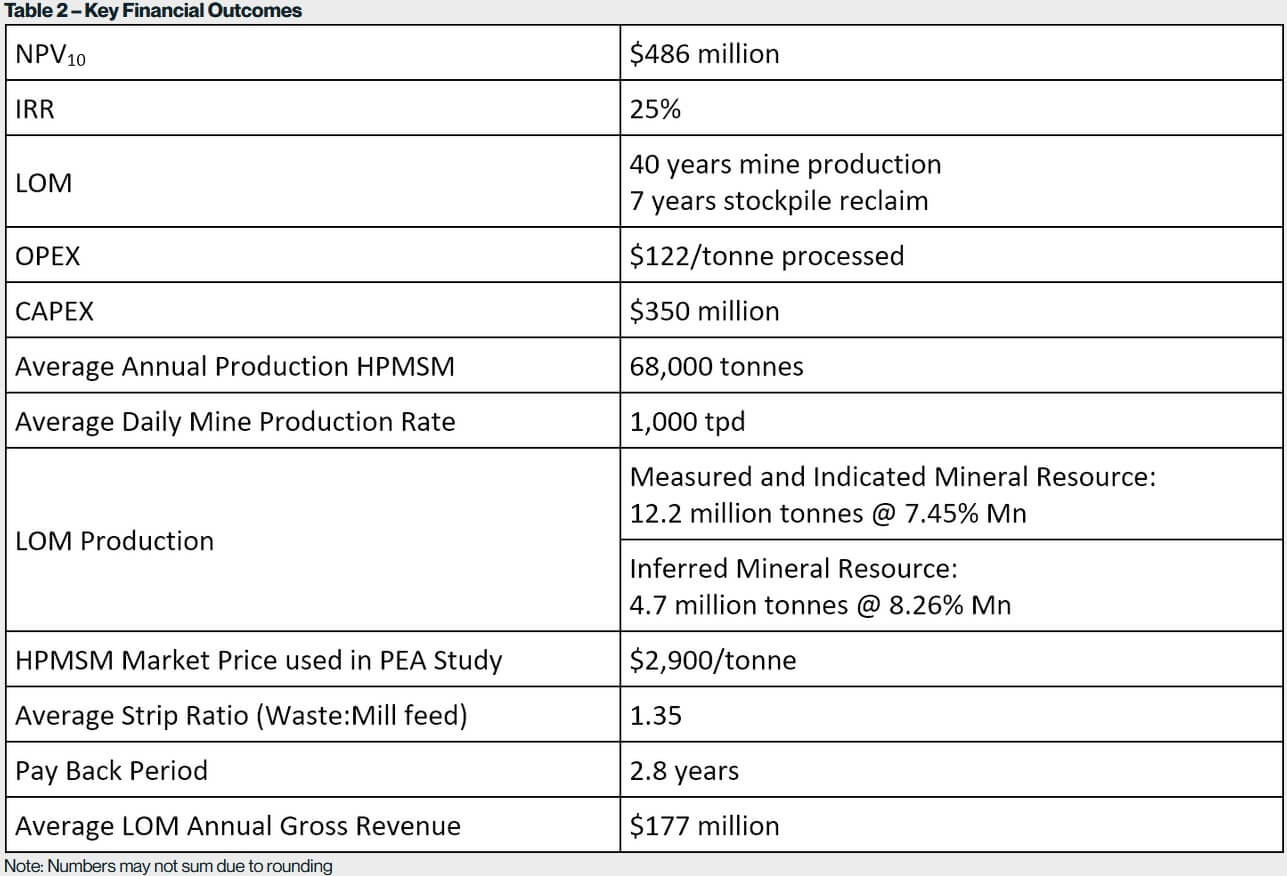

Positive PEA for our Battery Hill Project After-Tax NPV 10% of $486M US, and IRR of 25%

Sensitivity analysis shows after-tax NPV 10% of US $914 Million at US $4,200/t HPMSM

PEA Highlights:

- Robust Economics

- After-tax net present value using a 10% discount rate (“NPV10”): $486 million

- 25% internal rate of return (“IRR”)

- Capital costs (“CAPEX”) of $350 million with a payback of 2.8 years

- Average annual gross revenue of $177 million per year over the 47 years Project life

- Average annual gross revenue of $220 million over the first seven years

- Life of mine (“LOM”) operating cost (“OPEX”) of $122/t material processed

- HPMSM Market Price

- Base case market price of $2,900/t for battery-grade high-purity manganese sulphate (“HPMSM”) is well below the long-term forecast price of $4,200/t HPMSM estimated by CPM Group

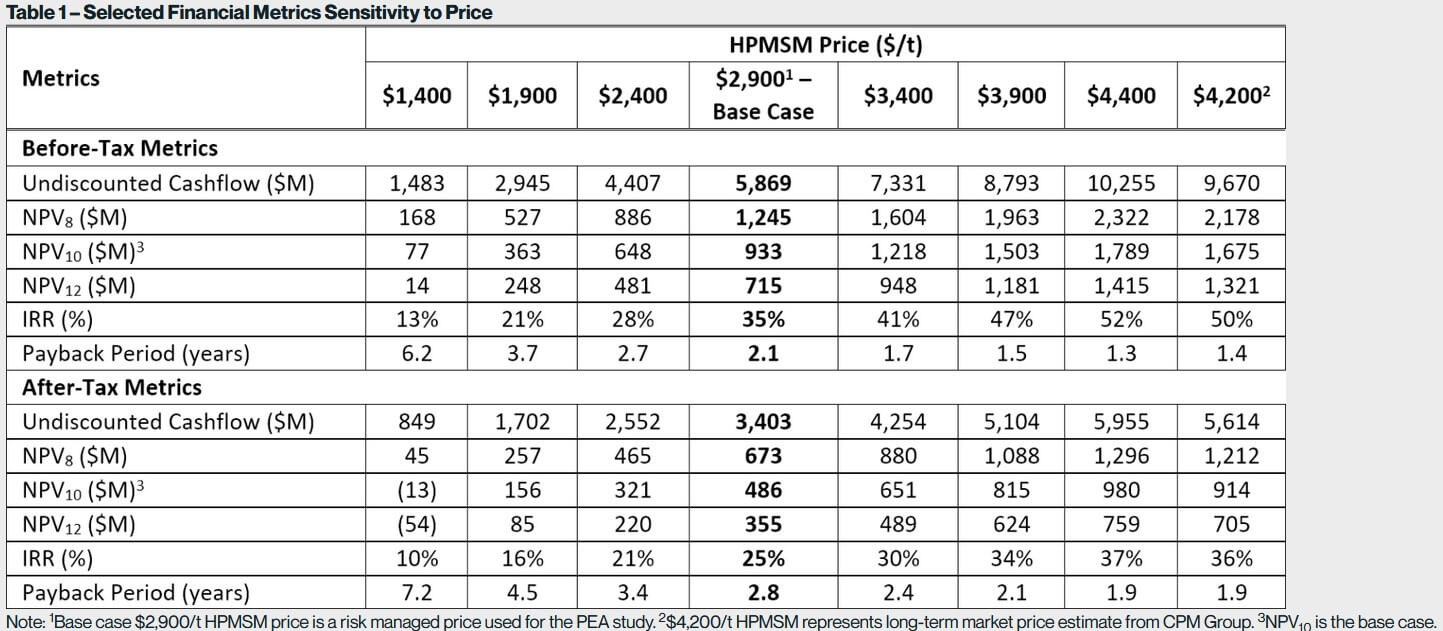

- Price Sensitivity

- Base case undiscounted after-tax cashflow: $3.4 billion

- Sensitivity analysis shows after-tax NPV10 reaches $914 million at $4,200/t HPMSM – see sensitivity analysis Table 1 below

- Long Mine Life

- 40-year mine production life and seven years of stockpile reclaim feed

- Total LOM production of 3.2 million tonnes of HPMSM

- Average annual HPMSM production of 68,000 tonnes over the LOM

- Average annual HPMSM production of 84,000 tonnes in the first seven years of production

- Low Environmental Impact

- Flowsheet produces a filtered residue leach product with initial acid-base accounting and non-acid generating test results showing no acid drainage risk

- Project Objectives

- Project is now advancing towards a pilot project, pre-feasibility study as well as advancing a drilling program to upgrade and expand manganese resources

Sensitivity Analysis:

Martin Kepman, CEO of Manganese X, states, “We are extremely pleased with the positive economics demonstrated by our PEA. Our Battery Hill Mineral Resource has the potential to be the most impressive manganese properties in North America and has several attributes that make it attractive for development and commercialization. Battery Hill has robust economics, strong value metrics and a short payback period for a relatively low capital investment. The PEA represents the most significant milestone to date for Manganese X and makes us the forerunner of becoming the first publicly traded company in Canada and the US to commercialize high-purity electric vehicle (EV) quality compliant manganese. Thanks to our proprietary extraction process, we can develop a superior quality manganese product by eliminating selenium, considered a toxic pollutant and yet utilized by some of the HPMSM producers worldwide to reduce their costs of production. Given selenium is a highly toxic element, its use negatively impacts the environment and is known to affect the quality of downstream products, particularly for high-end applications such as lithium-ion-battery production. Our final product should be able to justify a premium to the market price.”

Martin Kepman continues, “The Company has been working diligently on corporate development beyond the PEA and is currently in discussion with a number of interested parties. This is a very exciting time in history for manganese as it relates to battery chemistry and the EV revolution, making it an equally exciting time for Manganese X. We intend to be at the forefront of a domestic supply as well as meeting the expectations of North American battery manufacturers.”

The PEA is preliminary in nature; it includes Inferred Mineral Resources that are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as Mineral Reserves, and there is no certainty that the preliminary economic assessment will be realized. Mineral Resources are not Mineral Reserves and do not have demonstrated economic viability.

PEA Summary

Mineral Resource Estimate Update:

The Mineral Resource estimate has been reported in accordance with NI 43-101 and was prepared by Mercator Geological Services Ltd. (“Mercator”) with an effective date of 12 May 2022. The 2021 Mineral Resource statement has been renewed to reflect updated costs and an HPMSM price as per a market analysis report recently obtained. The Mineral Resource estimate is tabulated in Table 3.

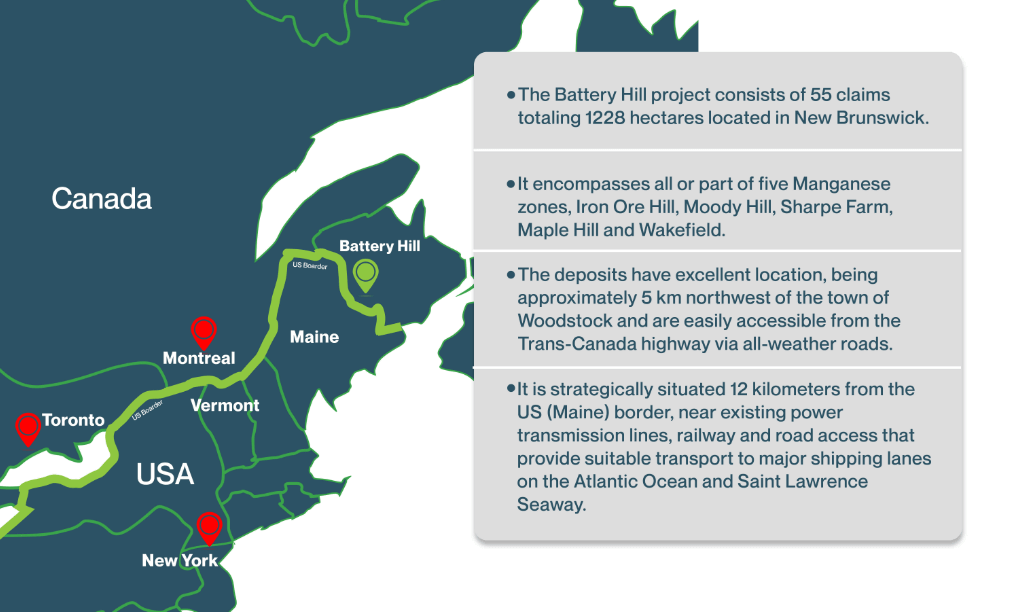

Infrastructure:

The Project is located approximately 6 km northwest of the town of Woodstock and is accessible to the east via a new two-lane road that connects with Highway 560. Key site infrastructure includes security and administration, crushing facility, process plant and ancillaries, sulphuric acid plant, mining facilities (truck shop and maintenance), waste rock storage facilities, run of mine mill feed stockpile and filtered residue storage area, sedimentation ponds, power, water and fuel supply and distribution. Filtered residue from the process plant will be trucked to the filtered residue storage area for the first 24 years of mine production after which residue will be trucked to the Moody Hill Pit 2 and backfilled.

Metallurgical Test Work:

Phase three of preliminary metallurgical test work completed by Kemetco Research Inc. (“Kemetco”) has resulted in the refinement of a conceptual flowsheet and estimated mass balance to support the PEA. Test work focused on defining key process steps to establish major equipment requirements, reagent consumption and manganese recovery. The following main conclusions highlight the results drawn from this test program:

- Leaching and neutralization optimization resulted in improved solid-liquid separation and allowed an incremental increase in recovery

- Leach extractions on Moody Central mineralization were between 83 and 88%

- Effective removal of calcium and magnesium from leach solutions was demonstrated with the removal of up to 90% of both elements from leach solution

- Crystallization of manganese sulphate from evaporated and purified feed solutions was readily achieved

- The overall recovery to HPMSM is estimated to be 78%

- Final neutralized and washed solid residue samples showed little or no acid generation potential and all had positive neutralization potential. Toxicity characteristic leaching procedure (TCLP) tests were negative for all elements of concern.

Metallurgical Test Work Recommendations:

- Leaching parameters, leach solution purification and the crystallization processes will require further definition and optimization for both recovery and impurity rejection

- Additional locked-cycle testing is required on leach and neutralization, purification, crystallization and bleed stream treatment

- Pilot plant testing will demonstrate the process and generate sufficiently large HPMSM samples for end-user testing.

Process Method:

The proposed process for treating Battery Hill manganese resources is a whole ore sulphuric acid slurry leach performed under conditions which result in formation of a filterable residue. Leach solution is neutralized with a calcium base, concentrated by evaporation and purified through a proprietary selective cation removal process. The purified liquor is then further evaporated to produce a crystalline manganese sulphate monohydrate product meeting all specifications for sale as a battery grade product.

Mining Method:

The PEA mine plan assumes conventional open pit mining using a contract mining equipment fleet at a total mining rate of 1.0 million tonnes per year to provide a mill feed of 365,000 tonnes per year, or 1,000 tonnes per day. The ultimate pits and mine plan use an elevated cut-off grade strategy to help drive the project economics. The use of a stockpile for mineralized material allows higher-grade material to be processed early in the mine life to enhance project economics and to sustain mill operations 24-hours per day, seven-days per week at a single, central processing facility. The mining operations will have a 40-year mine production life, with a two-year pre-production period, and seven years of stockpile reclaim feed.

Independent Qualified Persons Statements:

The PEA was prepared for Manganese X by independent Qualified Persons (QPs) as defined under NI 43-101 from Wood and Mercator and are listed below. The independent QPs have prepared and approved the scientific and technical information disclosed in this press release derived from their respective sections of the technical report:

- Paul Baluch, P.Eng., Technical Director Civil/Structural/Architectural, Wood

- Alan Drake, P.L.Eng., Manager Process Engineering, Wood

- Greg Gosson, P.Geo., Technical Director Geology and Compliance, Wood

- Matthew Harrington, P.Geo., Senior Resource Geologist, Mercator

- Paul Ténière, P.Geo., Senior Associate Geologist, Mercator

- Gil Violette, P.Eng., New Brunswick, Principal Hydrogeologist, Wood

- Piers Wendlandt, P.E., Principal Mining Engineer, Wood

Data Verification:

QP Harrington performed standard validation checks on the Mineral Resource model.

QP Drake visited the Kemetco testing facilities and had discussions with those who performed the test work, identified the drill holes and the intervals in which the metallurgical test samples were taken.

QP Gosson discussed with the marketing expert from CPM Group regarding the basis of their market analysis and price forecast.

QP Ténière visited the Project site and compared select core intervals with original drill logs and sampled intervals, collected independent witness samples, reviewed quality assurance and quality control procedures, and completed a field inspection.

QP Violette visited the Project site during which he viewed drill core, completed field inspections of the Moody Hill target and surrounding areas, and assessed local infrastructure.

A description of the data verification methods for the Mineral Resource estimate is contained within the technical report previously filed on Manganese X’s SEDAR profile (NI 43-101 Technical Report Battery Hill Project Mineral Resource Estimate, Woodstock Area, New Brunswick, Canada with effective date 18 June 2021).